Joby Aviation is reimagining air travel with electric aircraft built from the ground up—manufacturing precision components, analyzing flight telemetry, and optimizing performance at every stage of production. But with multiple factory sites and a massive influx of telemetry data, their legacy ingestion architecture couldn’t keep up. Delays, duplicated data, and operational complexity slowed down innovation and made it difficult to turn real-time signals into real-time action. With Zerobus Ingest, part of Lakeflow Connect, Joby has transformed its data infrastructure—streaming gigabytes per minute from thousands of devices directly to the lakehouse, all with sub-five-second delivery. What once required brittle pipelines and multiple hops now happens in seconds, enabling faster decisions, tighter feedback loops, and a smarter path from factory to flight.

Multiple data hops left innovation on the tarmac

Joby Aviation is a vertically integrated aviation company pioneering electric vertical takeoff and landing (eVTOL) aircraft for fast, quiet, and clean urban mobility. From manufacturing precision components to analyzing flight telemetry, Joby’s end-to-end ownership of the technology stack enables rapid iteration and continuous improvement. But with full ownership comes a massive data challenge—one that requires a scalable and intelligent approach to data engineering.

Joby needed a reliable way to ingest and operationalize high-volume telemetry and factory data across multiple sites. “We’re manufacturing our own aircraft, collecting flight analytics, and running a full production pipeline. All of that generates data, and we need to capture and connect it—across different factories, machines, and use cases—to make better decisions and accelerate innovation,” explained Dominik Müller, Factory Systems Lead at Joby Aviation. Their goal was to make this data accessible to AI agents, business dashboards, and analytical workflows in near real-time. All without overwhelming their engineering teams.

Joby’s use cases span the entire data lifecycle. In the factory, they ingest telemetry from connected machines to monitor equipment performance, improve traceability, and feed AI agents with high-fidelity signals from the manufacturing floor. Flight data from their aircraft is analyzed to track critical metrics and inform iterative improvements. This operational data is also used to power real-time dashboards that provide leadership with visibility into key processes and performance trends. Meanwhile, historical data is archived to support machine learning model training, safety analysis, and regulatory compliance.

Each of these use cases depends on ingesting data from geographically dispersed factory sites, where conditions vary widely. This made data consistency and real-time availability a major hurdle. “Every factory is different. The machines are different, the internet connections are different, and so are the dependencies,” said Müller. “That variability meant we needed a way to offload telemetry quickly and reliably, no matter the site. These connections are often ephemeral, so they need to build in resilience on the ground and in the cloud.”

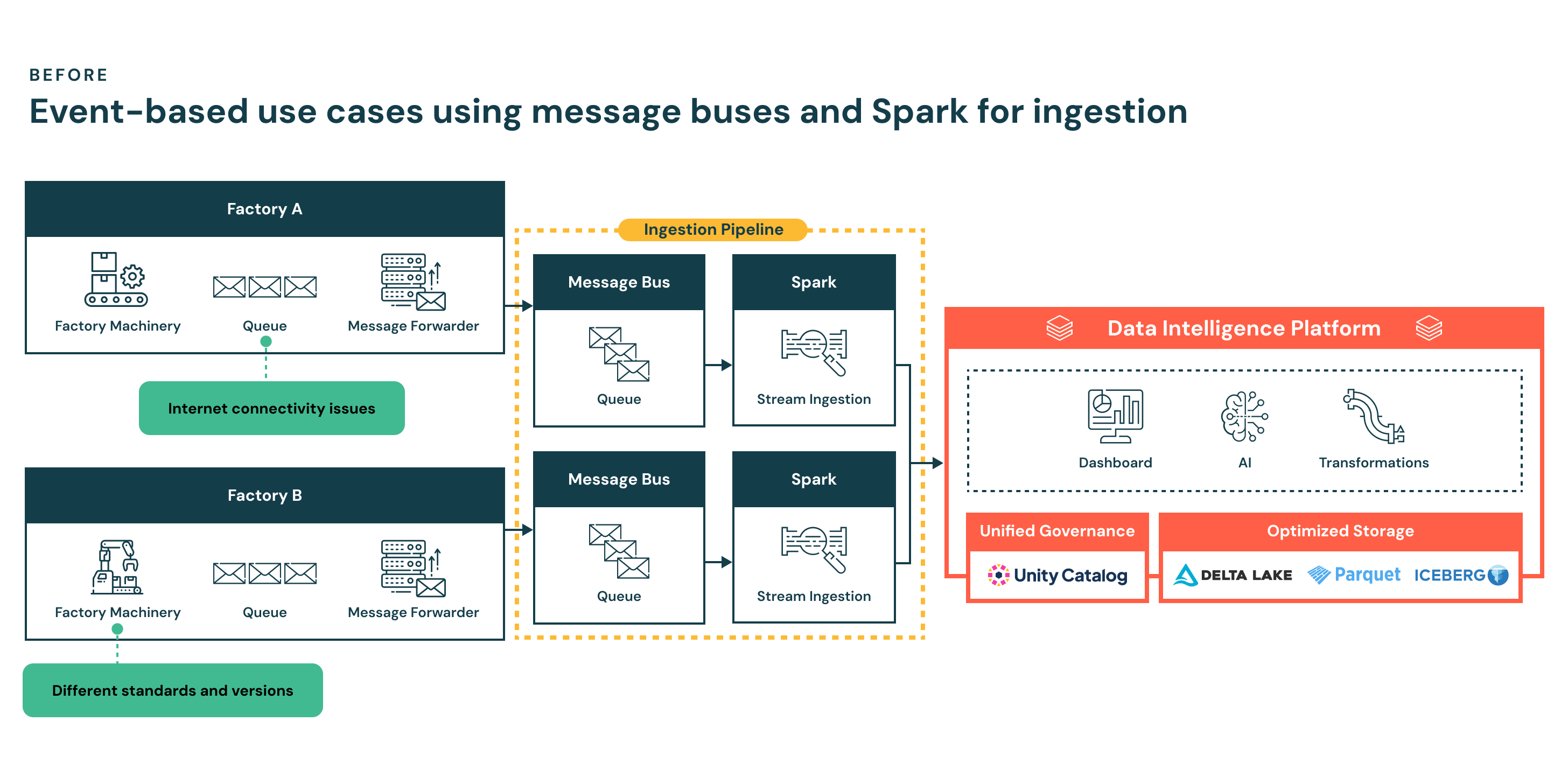

Prior to Databricks, Joby relied on a multi-hop architecture using a message bus and Spark ingestion jobs to move data from local factory agents into the cloud. While this approach ensured durability, it added significant complexity to their ingestion infrastructure. According to Müller, “That two-hop architecture introduced operational overhead, duplicated data, and required additional tools and expertise to manage.”

As the volume and velocity of data continued to grow, this architecture became increasingly difficult to maintain. They needed a more streamlined solution that could handle high-throughput telemetry, scale across thousands of connections, and reduce operational friction. These challenges led Joby to adopt Databricks Lakeflow Connect, with the goal of simplifying ingestion, reducing infrastructure burden, and accelerating time to insight across their data pipeline.

Ingesting telemetry at scale with Lakeflow Connect

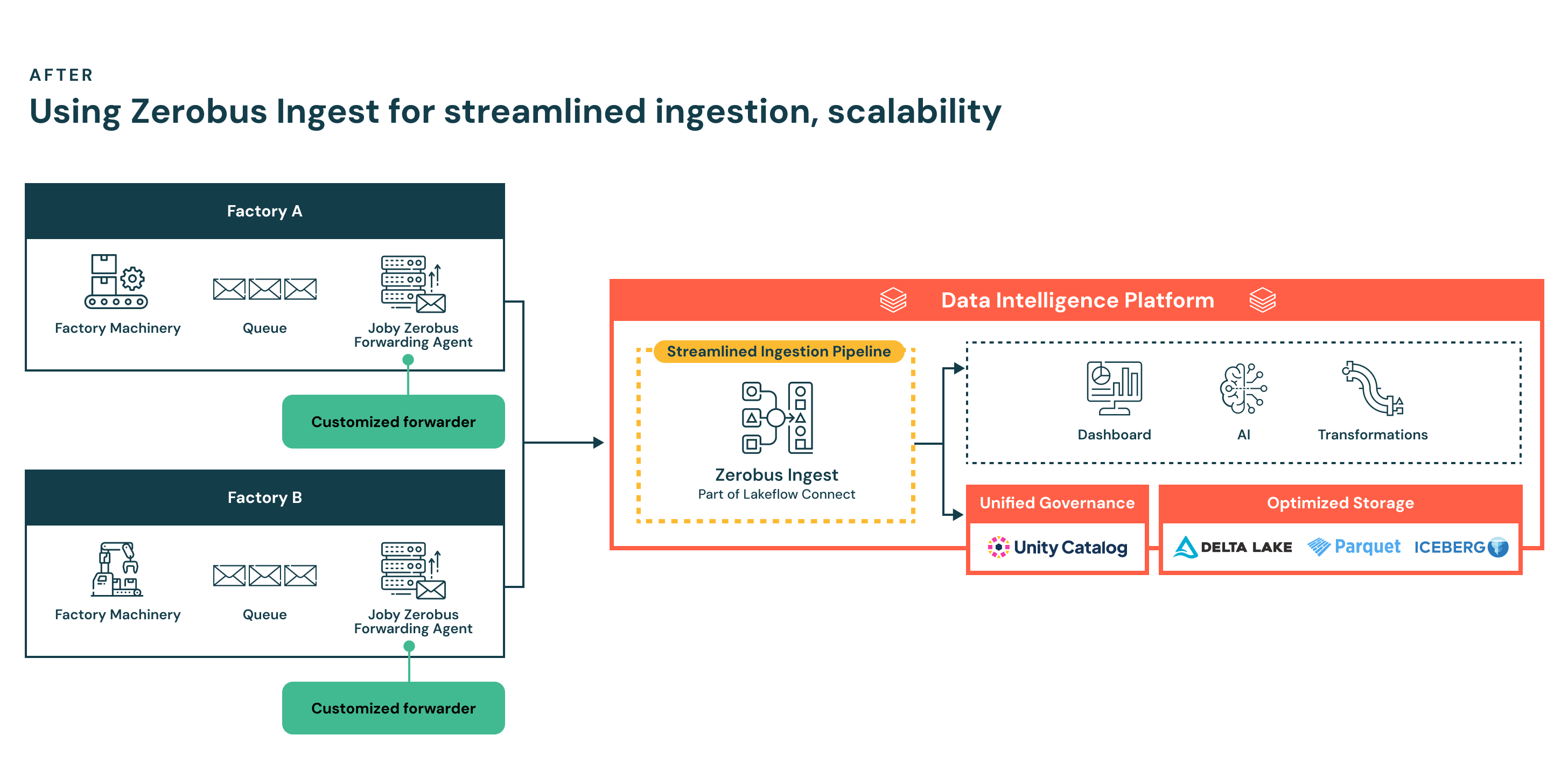

To simplify and scale their ingestion architecture, Joby turned to Databricks Lakeflow Connect. This unified, low-maintenance ingestion solution enables data to flow directly from source systems to the lakehouse.

The centerpiece of this transformation was Zerobus Ingest, a new direct write API that streamlines telemetry ingestion. Instead of relying on Spark jobs to pull from Kafka-like queues, Joby’s on-premise agents now push telemetry data directly to Delta tables with just one hop. “We’ve eliminated the message bus, ingestion jobs, and data duplication. Now, we just push directly to Databricks. There’s no extra infrastructure to maintain, and no latency caused by middle layers,” said Müller.

Zerobus Ingest is a high-performance, serverless ingestion service purpose-built for operational data sources like IoT, telemetry, and clickstreams. For Joby, it meant that each factory site could use a customized on-premises agent to stream gigabytes of sensor and machine data per minute with near real-time visibility. “Every site is different, so we needed something customizable but easy to deploy,” explained Müller. “With the Zerobus Ingest SDK, we built plug-and-play agents that integrate seamlessly into our existing pipelines. It gave us full control.”

The architecture is both simplified and intelligent. Once data is written to Delta tables via Zerobus Ingest, it’s immediately accessible across Joby’s analytics and AI stack. Spark Declarative Pipelines transform raw telemetry into structured insights. Teams across the business can act on fresh data almost instantly, supporting everything from factory traceability to flight performance analysis. As Müller put it, “With just a few seconds of latency, we’re powering dashboards, triggering alerts, and feeding downstream models.”

Crucially, Zerobus Ingest integrates tightly with the broader Databricks Data Intelligence Platform. It uses Delta Lake as its storage foundation—ensuring performance and schema enforcement—and Unity Catalog for unified governance and security. From the moment a record is written, it’s governed, discoverable, and ready for use across analytics, machine learning, and compliance workflows.

Zerobus Ingest has reshaped how Joby approaches operational telemetry. Müller explained, “We can write from thousands of devices to the same table, simultaneously, which helps with delivering timely insights.” Instead of engineering around architectural limitations, their data now flows natively (from factory to lakehouse), with the simplicity and reliability needed to support high-stakes innovation.

Faster insights, fewer moving parts

By adopting Zerobus Ingest, Joby dramatically reduced the complexity and cost of its telemetry ingestion infrastructure while unlocking the speed and scale needed to fuel its innovation cycle.

Before Databricks, each factory’s telemetry had to pass through a message bus and be processed by separate ingestion jobs, creating delays, operational risk, and duplicated data. With Zerobus Ingest, those hops are gone. Data now flows directly from Joby’s on-premises agents to their Delta tables with minimal latency and no extra infrastructure to manage. According to Müller, “With Zerobus Ingest, we’re pushing gigabytes of telemetry per minute to the lakehouse from our manufacturing sites. We no longer worry about message queues or fragile pipelines.”

The impact is clear. Every data record is made queryable within five seconds, making it fast enough to power real-time dashboards, surface urgent alerts, and support time-sensitive decisions. Joby’s engineers and business analysts can now work with near real-time data, enabling a tighter feedback loop between factory operations and performance optimization. “Now, telemetry is a real-time asset. Within seconds, we know if something’s trending in the wrong direction and can take action,” explained Müller.

Just as importantly, Zerobus Ingest has allowed Joby to scale without reinventing their architecture. Each connection supports up to 100 MB/sec of throughput, and the system handles thousands of concurrent streams—critical for a growing enterprise with multiple factory floors and a rapidly expanding sensor footprint. “It’s not just that Zerobus Ingest is fast; it scales with us. We didn’t have to redesign anything to support more sites, more devices, or more data,” explained Müller.

As they continue to innovate, Joby sees their stack as a strategic advantage. As Müller put it, “Getting data off the factory floor and into the hands of decision-makers now happens in seconds. That changes what’s possible.”