How Data Intelligence is Accelerating IT/OT Convergence

Unifying Aveva’s Industrial Data with Databricks: Data Intelligence as the foundation for IT/OT Convergence

Summary

- Data-Driven Competitiveness: Databricks natively integrates with Aveva CONNECT data services, enabling industrial enterprises to access advanced analytics and AI toolchains like AI/BI and the Mosaic AI Agent Framework. This integration democratizes real-time insights into equipment performance, production quality, and operational bottlenecks across the enterprise through natural language and AI agents.

- Scalable Intelligence: The data lakehouse architecture supports scalable, real-time analytics, allowing industrials to monitor and improve key performance indicators, predict maintenance needs, and optimize production processes. This scalable intelligence empowers operations teams to scale their expertise across the organization’s entire operational footprint, comprising millions of sensors and devices.

- Robust governance: Industrials can confidently maximize data value while simultaneously reducing regulatory risks, preventing costly data breaches, and building stakeholder trust, while accelerating data and AI-driven innovation.

The traditional boundaries between operational systems and business intelligence are dissolving. As factories, utilities, and infrastructure generate terabytes of sensor data daily, made accessible through operational technology (OT) systems like Aveva CONNECT, a new paradigm is emerging. One where the convergence of information technology (IT) and OT unlocks unprecedented value through Data Intelligence. With Data Intelligence, everyone from operators to executives can interact with industrial systems through natural language, detect anomalies before they become costly, and plan production based on real-time market data. Organizations mastering this convergence are transitioning to more profitable business models and realizing a lean enterprise.

When OT data from Aveva systems (asset hierarchy, equipment performance, and atmospheric sensors) merges with IT data (market data, resource plans, and supply chain forecasts), a complete operating picture of the value chain becomes visible. This comprehensive perspective enables a repeatable way to infuse AI into business processes and use cases, from root cause analysis and production flow optimization to energy and resource efficiency.

Demonstrating Convergence with Compressor Monitoring

Monitoring asset performance from critical infrastructure like compressors is critical to resilient operations. While operations collect vast volumes of sensor and equipment data, this data is often spread across multiple systems and inaccessible to operators in the field or machine learning experts in the office at the right time with the right context. The Aveva CONNECT integration with Databricks makes monitoring asset performance repeatable and scalable. Let’s show you how.

Scalable Integration of Varied Industrial Data

The first step is unifying data into a Lakehouse architecture, an open data management architecture that combines the flexibility, cost-efficiency, and scale of data lakes with the data management and ACID transactions of data warehouses. The standardized bidirectional integration enabled by CONNECT via Delta Sharing makes OT data appear natively alongside all other data sources within Databricks. This data architecture allows for the holistic monitoring of thousands of compressors within the OT data catalog to be combined with text-based maintenance records and real-time high-fidelity weather data catalogs. Once unified through a medallion architecture, visualization and artificial intelligence become easy through AI-assisted tools like AI/BI and the Mosaic AI Agent Framework built into the Databricks Platform.

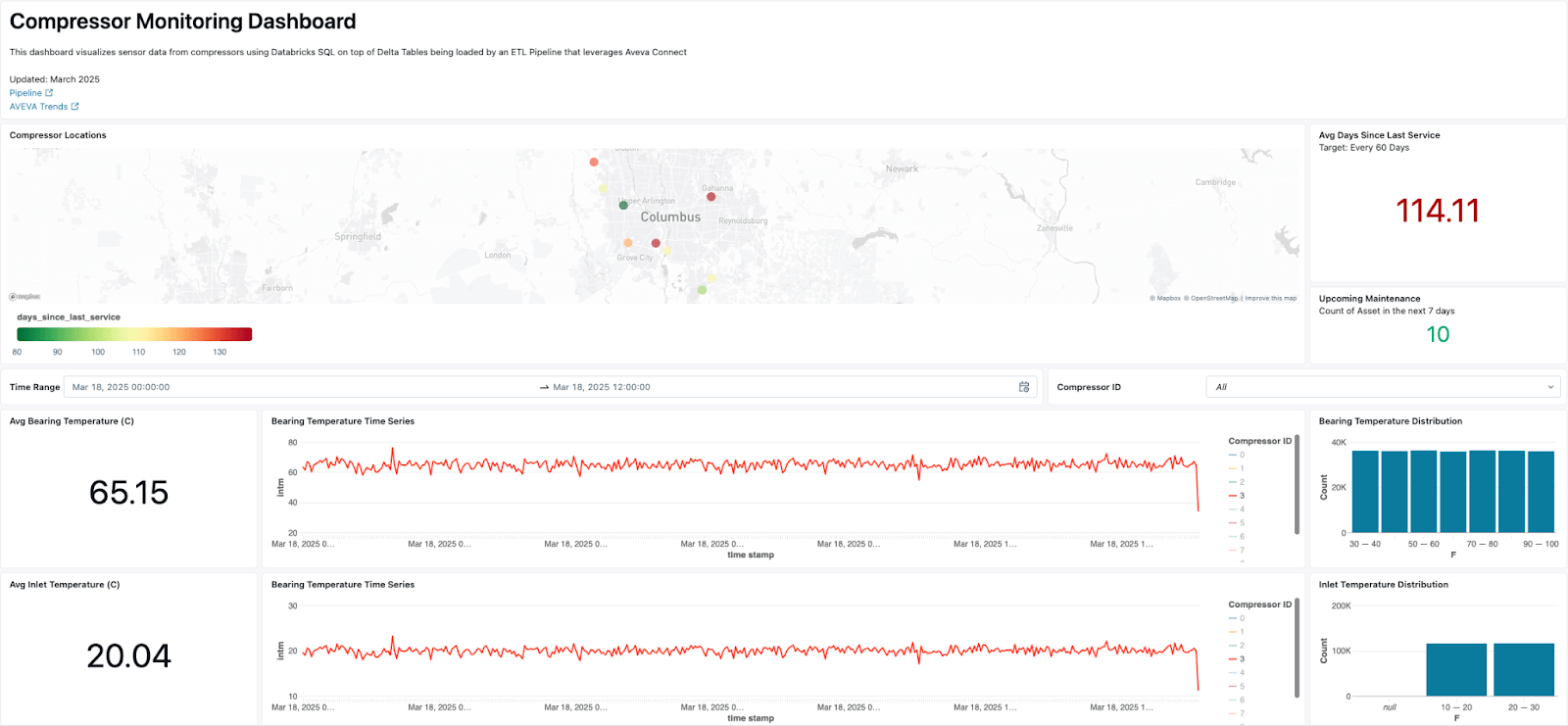

The dashboard above, built on Databricks AI/BI, visualizes time-series data streaming in from sensors located on a collection of compressors. Readings on attributes such as bearing temperature or inlet temperature allow for real-time monitoring of the health and performance of these assets. Advanced algorithms like multimodal anomaly detection can be applied to the converged time-series signal and real-time weather conditions, improving the operational picture for operations personnel.

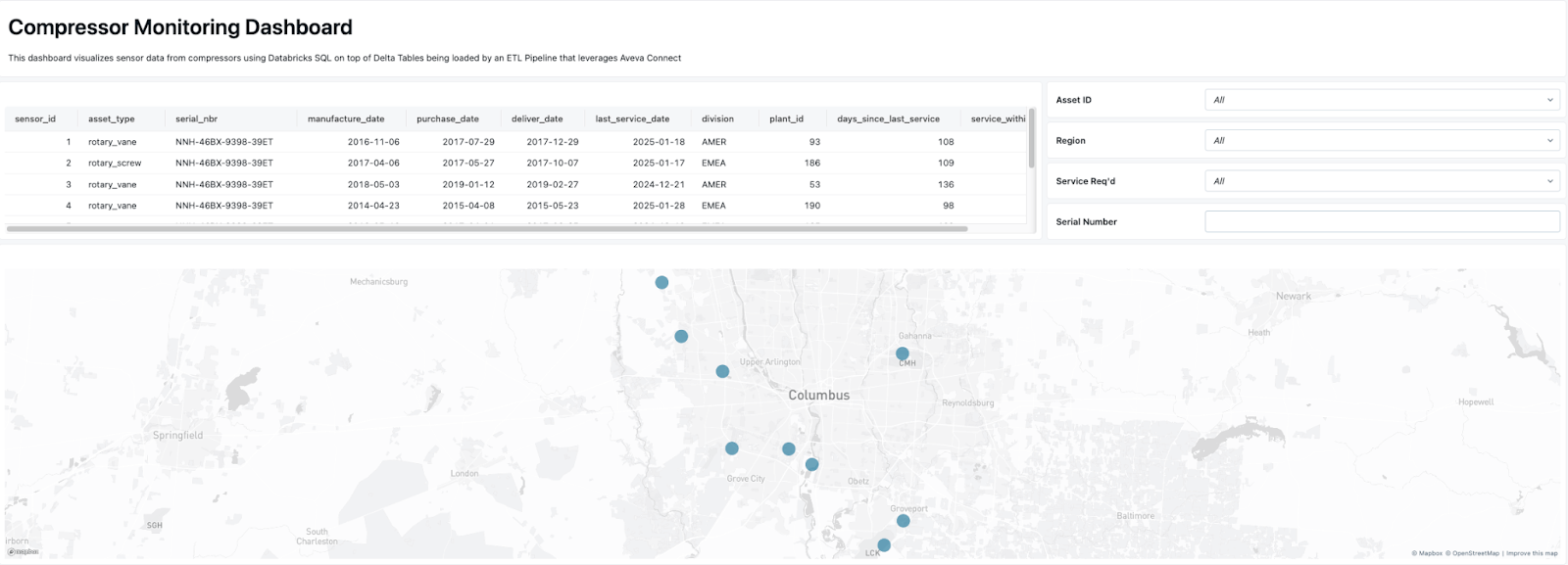

Governing Industrial Data for All

With data visible and fully governed in a central location, operations teams can view asset details tailored to their roles and attributes. Below, we can see information displayed regarding asset types, manufacturing details, and the service information for respective compressors. This view will automatically reflect the access permissions of the logged-in user, so a maintenance user may only see service information, while a factory manager could see all the financial KPIs alongside service information without needing to duplicate data or the dashboard.

Data intelligence reshapes industries

Expanding Data Impact with Natural Language Business Intelligence

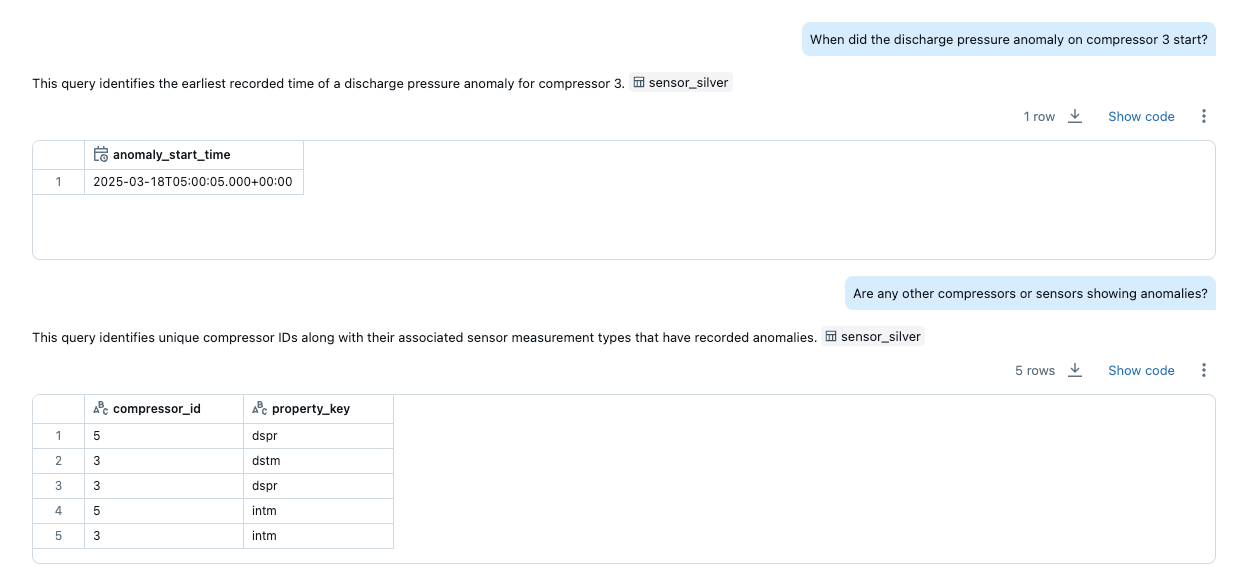

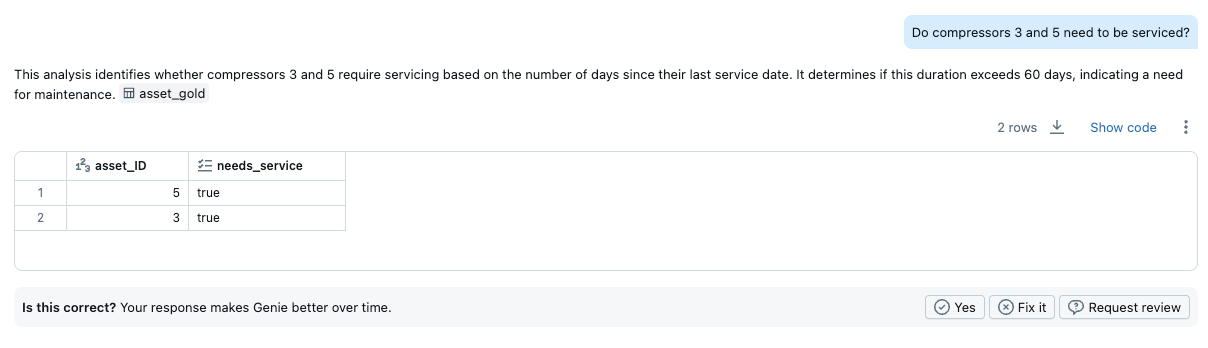

To democratize analytics consumption, AI/BI also provides natural language capabilities that can empower domain experts to obtain insights without relying on technical teams equipped with traditional analysis skills, such as SQL. As an example, users can leverage Genie to ask follow-up questions:

The user can also ask questions related to maintenance service schedules for these compressor units:

With access to IT and OT made simple, lean operations become possible through the delivery of use cases such as predictive maintenance, energy optimization, real-time quality control, and supply chain synchronization. Enterprises that are embracing this convergence are solving today's operational challenges and building a foundation to continuously innovate as AI transformation reshapes their business processes.

Data Intelligence as the foundation for IT/OT Convergence

Industrials embracing Data Intelligence on Databricks through the unification of Aveva OT data alongside other major enterprise data systems like SAP, Salesforce, Workday, Kinaxis, and more provides a comprehensive understanding of an organization’s data and its usage. The example of compressor health monitoring is one of many use cases industrials are doing today to reshape business processes with AI agents. By balancing human expertise and technology, industrials are achieving cost savings through reduced unplanned downtime, increased profits through responsive production based on real-time market pricing, and reductions in safety incidents through proactive alerts of hazardous environmental conditions. Ultimately, the Databricks Platform plays a critical role in maximizing the value of your enterprise systems like Aveva through data-driven competitiveness, scalable intelligence, and robust governance through the orchestration of Data Intelligence.

Rewatch Unlocking Industrial Intelligence with Aveva and Agnico Eagle and Aveva and Databricks IT-OT Convergence for Industrial Intelligence at Scale from Data + AI Summit 2025, showing how the seamless, no-code, zero-copy solution - powered by Delta Sharing and CONNECT - enables companies to combine IT and OT data effortlessly.

Never miss a Databricks post

Sign up

What's next?

Data Science and ML

October 1, 2024/5 min read